Home /

Expert Answers /

Chemical Engineering /

when-designing-equipment-for-high-temperature-and-high-pressure-service-the-maximum-allowable-stres-pa541

(Solved): When designing equipment for high-temperature and high-pressure service, the maximum allowable stres ...

When designing equipment for high-temperature and high-pressure service, the maximum allowable stress as a function of temperature of the material of construction is of great importance. Consider a cylindrical vessel shell that is to be designed for pressure of 150 bar (design pressure). The diameter of the vessel is 3.2 m, it is 15 m long, and a corrosion allowance of 6.35 mm (1/4??) is to be used. Construct a table that shows the thickness of the vessel walls in the temperature range of 300 to 500°C (in 20°C increments) if the material of construction is ASME SA-240-grade 316 stainless steel.

write al steps and no copied solution please.

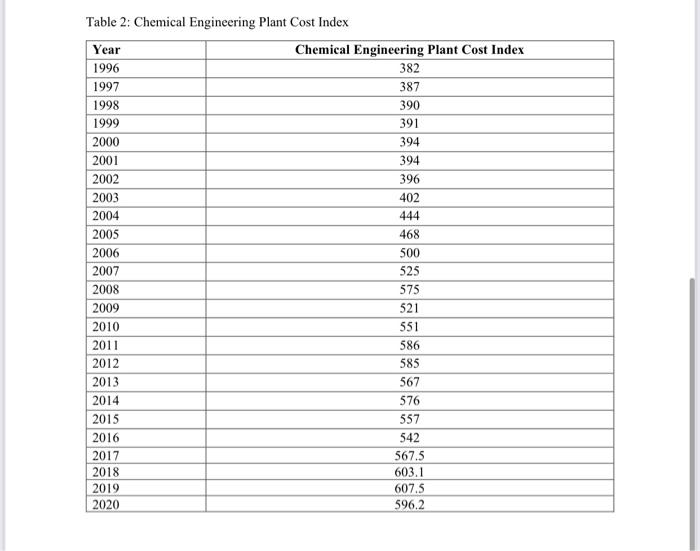

Table 2: Chemical Engineering Plant Cost Index Year Chemical Engineering Plant Cost Index 1996 382 1997 387 1998 390 1999 391 2000 394 2001 394 2002 396 2003 402 2004 444 2005 468 2006 500 2007 525 2008 575 2009 521 2010 551 2011 586 2012 585 2013 567 2014 576 557 2016 542 2017 567.5 2018 603.1 2019 607.5 2020 596.2 2015

Expert Answer

We use ASME B&PV Code Section VIII Div 1 for calculations. Allowable stresses are available in Section