(Solved): STEAM GENERATOR MODELLING INTRODUCTIONThe low cost and the high starting torque of universal motors ...

STEAM GENERATOR MODELLING

- INTRODUCTION

The low cost and the high starting torque of universal motors make it as the widely used motor in washing machines. Controlling the speed of a washing machine is a major challenge. Since the applied torque to the motor is not consistent, the machine’s speed varies. The application of torque to the motor is disrupted by the unpredictable placement of laundry. Furthermore, while it is in a state of transition (from wash to dehydration - spin), the laundry’s location in the drum shifts, causing rapid and intense torque fluctuations. Tuning the controller online on the actual machinery is not recommended for safety reasons.

LOAD MODELING

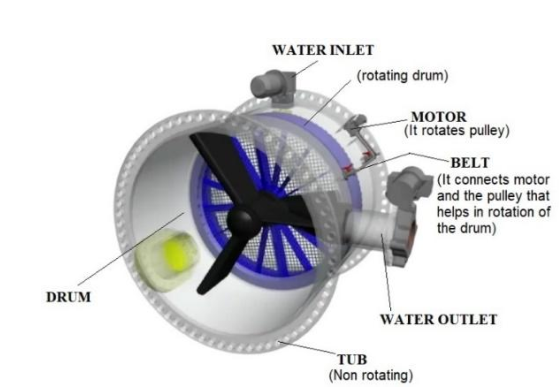

A washing machine’s major driving components are the motor, power transmission system (pulley and shaft), and drum. The inner working components of a washing machine are depicted in Figure 1.1. The rotation of the drum of a washing machine washes the clothes. When power is supplied to the washing machine, the motor starts rotating. The belt which connects the pulley to the motor helps in the rotation of the drum. Washing, rinsing, and spinning are the three basic phases in every washing machine cycle. The initial step is washing.

The purpose of washing is the removal of dirt from clothes. Next, the clothes undergo rinsing to remove detergent. Once washing and rinsing are finished, the next step is dehydration

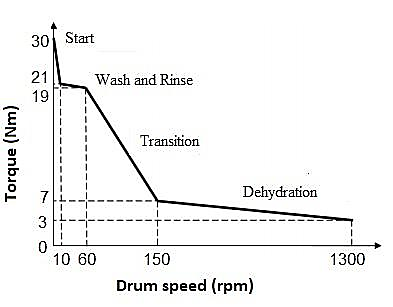

i.e., spinning. At different stages, the washing machine requires different rotational speeds. For example, in rinse mode machine requires only 45 rpm speed whereas, in dehydration mode, it requires 1000 rpm. The load torque of the washing machine also changes during the entire process. Abrupt torque fluctuations are the result of force by the falling laundry, a varying moment of inertia, and high viscosity between the drum and the

laundry. This can be observed when the machine is changed to dehydration mode. Figure 1.2. Briefs the relation between torque and drum speed at different stages of washing. The data in this diagram are representative and vary in terms of the number of clothes in the washing machine and the structure of the washing machine.

Figure 1.1: Horizontal Washing Machine Internal Components

Figure 1.2: Torque Vs Speed of the Drum at Different Modes of Washing

DEVELOP THE MATHEMATICAL MODELLING OF THE SYSTEM.

BUILD THE PROCESS MODEL IN MATLAB/SIMULINK

DEFINE THE MODEL PARAMETERS

SIMULATE THE MODEL BY:

Plotting the results for analysis