(Solved): Process Control and Instrumentation A CSTR is installed with a temperature feedback control loop for ...

Process Control and Instrumentation

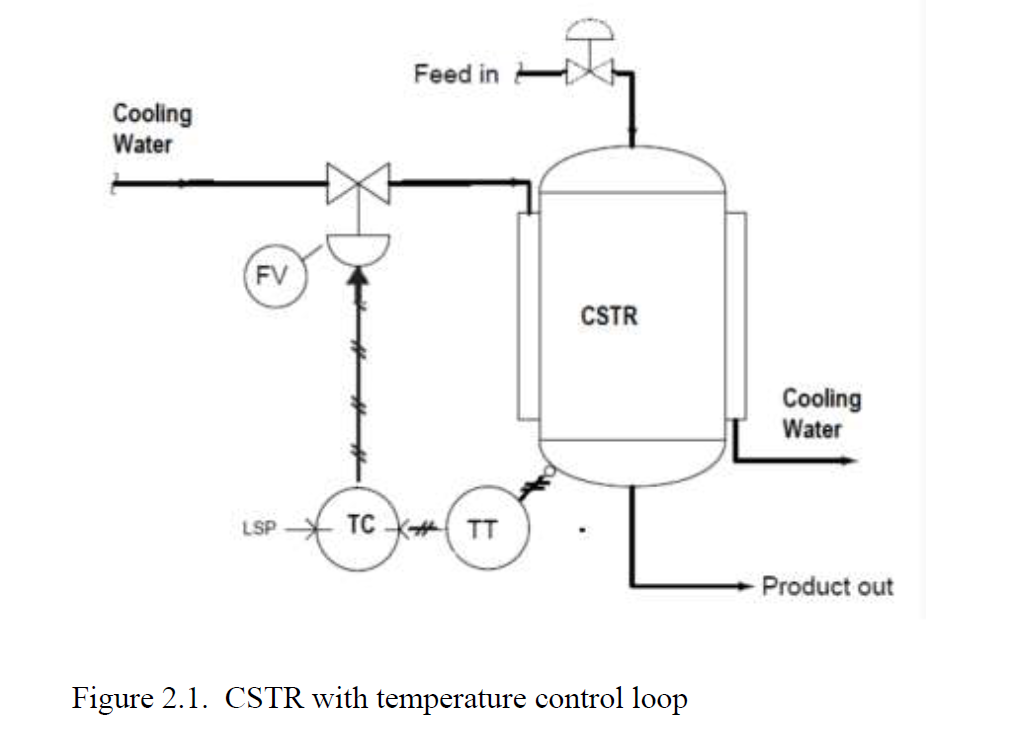

A CSTR is installed with a temperature feedback control loop for

cooling the reactor as shown

in Figure 2.1 to ensure that the reactor will not overheat, and can

be maintained at the optimal

operating condition.

From the information given by the control consultant vendor and

the instrumentation manual,

the dynamics of the valve is very fast compared to the whole

process and the transfer function is

represented as a static gain. The valve has a maximum flow of 12

gal/min. The temperature

transmitter is known to have first order dynamics with a time

constant of 1 min and gain of 1

(psig/ ?C). All instrument signal is pneumatic.

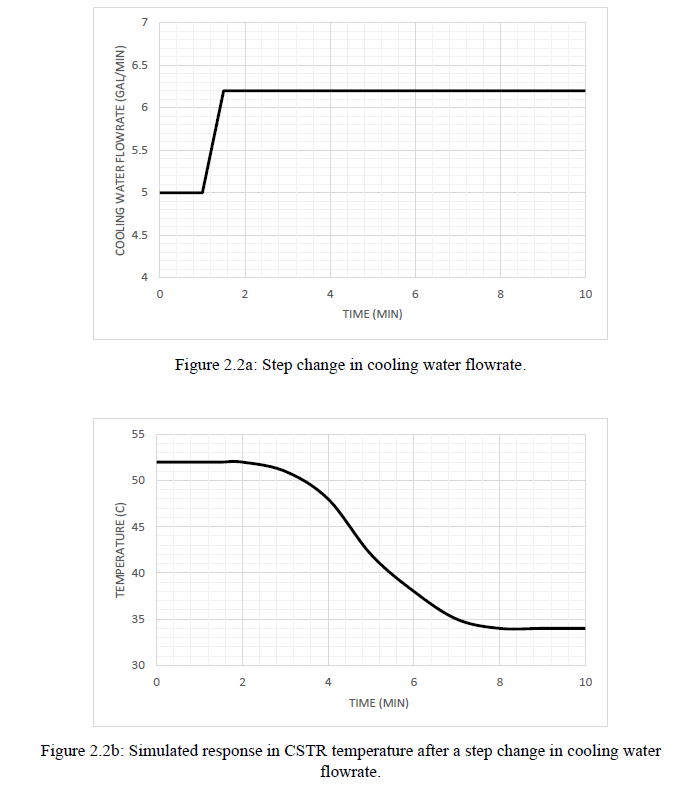

The consultant appointed by the company provided the dynamic

simulation of the CSTR to get

step responses for the temperature. Figure 2.2 shows the CSTR

temperature response with a

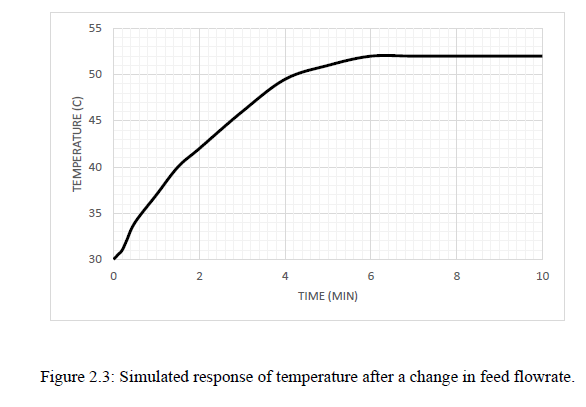

step change in cooling water flow (in gpm) at 1 minute. Figure 2.3

shows the temperature

response after a step change of 1 gal/min in the feed flowrate to

CSTR. From the information

obtained from the consultant, the response of CSTR temperature to a

step change in feed

flowrate is known to be well approximated with a first order model,

while the response of T to

a step change in cooling water flowrate is higher order and can

best be approximated with a

FOPDT model.

a) Based on the step responses, find all the temperature control

system transfer function,

including for all the instrumentation. Show all working. The

working on the graphs for model

estimation must also be clearly shown.

b) Draw the feedback control block diagram. Use a proportional

controller for the system.

Please put in the transfer functions derived in the appropriate

blocks, with the suitable labels

for the variables according to the system.

c) Derive the servo and regulator transfer function for this

closed-loop control system and

analyse the stability of the temperature control system using the

Routh stability criteria. Find

the range of controller gain Kc that make the feedback control

system stable.

d) Find the tuning parameters for the PID controller using the

Cohen Coon method.

Approximate GPRC to a standard form of first order plus dead time

(FOPDT) by setting the

largest ? to become the time constant of the FOPDT model and the

remaining ?’s should be

added up to become the time delay (ie dead time).

e) Determine the offset for servo and regulator problems for the

step change of magnitude 10 ?C

in set point and 2 gal/min in the feed flowrate respectively, if a

proportional controller with the

tuning parameter calculated using the Cohen and Coon method.