Home /

Expert Answers /

Operations Management /

consider-the-following-three-station-production-line-with-a-single-product-that-must-visit-station-pa346

(Solved): Consider the following three-station production line with a single product that must visit station ...

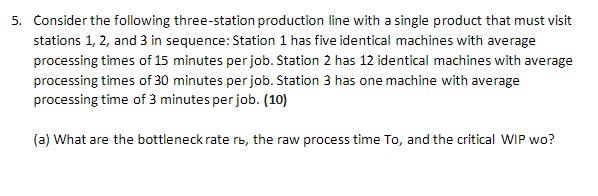

Consider the following three-station production line with a single product that must visit stations 1,2 , and 3 in sequence: Station 1 has five identical machines with average processing times of 15 minutes per job. Station 2 has 12 identical machines with average processing times of 30 minutes per job. Station 3 has one machine with average processing time of 3 minutes per job. (10) (a) What are the bottleneck rate rb, the raw process time To, and the critical WIP wo?

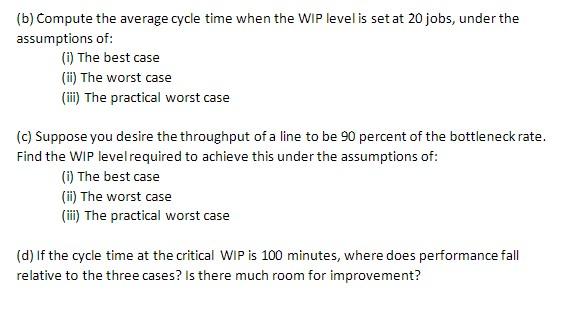

(b) Compute the average cycle time when the WIP level is set at 20 jobs, under the assumptions of: (i) The best case (ii) The worst case (iii) The practical worst case (c) Suppose you desire the throughput of a line to be 90 percent of the bottleneck rate. Find the WIP level required to achieve this under the assumptions of: (i) The best case (ii) The worst case (iii) The practical worst case (d) If the cycle time at the critical WIP is 100 minutes, where does performance fall relative to the three cases? Is there much room for improvement?

Expert Answer

(a) To determine the bottleneck rate (rb), we need to identify the slowest station in the production line. Station 2 has the longest processing time p