Home /

Expert Answers /

Mechanical Engineering /

consider-a-regenerative-vapor-power-cycle-using-an-open-and-a-closed-feedwater-heater-similar-in-de-pa250

(Solved): Consider a regenerative vapor power cycle using an open and a closed feedwater heater similar in de ...

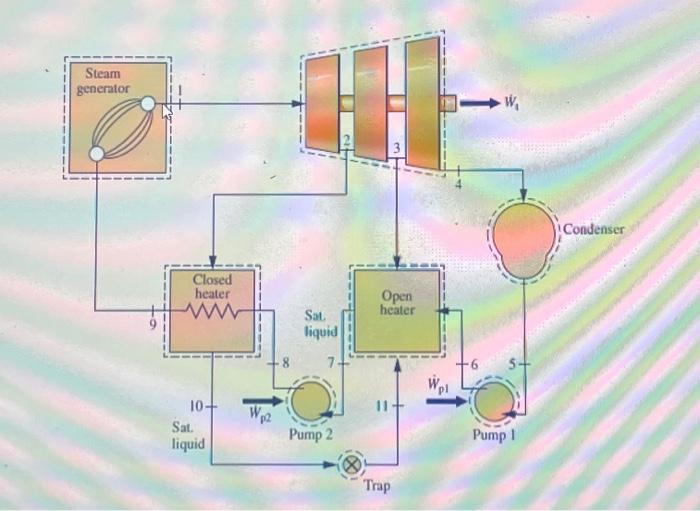

Consider a regenerative vapor power cycle using an open and a closed feedwater heater similar in design to that shown in the figure below. Steam enters the turbine at , state 1 , and expands isentropically in three stages to a condenser pressure of 45 , state 4. Saturated liquid exiting the condenser at state 5 is pumped isentropically to state 6 and enters the open feedwater heater. Between the first and second turbine stages, some steam is extracted at , state 2 , and diverted to the closed feedwater heater. The diverted steam leaves the closed feedwater heater as saturated liquid at , state 10 , undergoes a throttling process to 0.2 , state 11, and enters the open feedwater heater. Steam is also extracted between the second and third turbine stages at , state 3 , and diverted to the open feedwater heater. Saturated liquid at 0.2 MPa exiting the open feedwater heater at state 7 is pumped isentropically to state 8 and enters the closed feedwater heater. Feedwater exits the closed feedwater heater at , state 9 , and then enters the steam generator. Each turbine stage and the pumps have an isentropic efficiency of .

If the net power developed by the cycle is , determine: (a) the percent cycle thermal efficiency. (b) the mass flow rate into the first turbine stage, in . (c) the magnitude of the rate of heat transfer from the working fluid as it passes through the condenser, in MW.