Home /

Expert Answers /

Mechanical Engineering /

2-the-design-of-transmission-shafts-is-important-for-bespoke-drive-applications-often-this-invol-pa119

(Solved): 2. The design of transmission shafts is important for bespoke drive applications. Often this invol ...

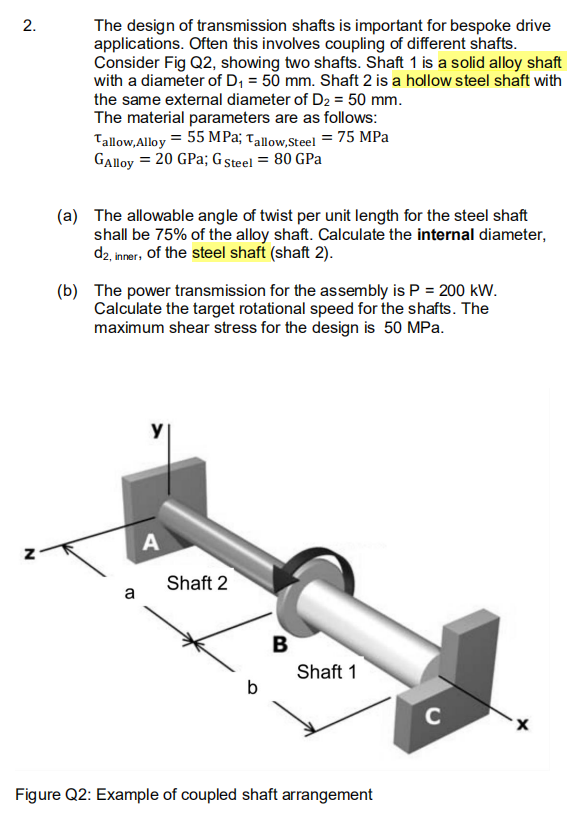

2. The design of transmission shafts is important for bespoke drive applications. Often this involves coupling of different shafts. Consider Fig Q2, showing two shafts. Shaft 1 is a solid alloy shaft with a diameter of D1 = 50 mm. Shaft 2 is a hollow steel shaft with the same external diameter of D2 = 50 mm. The material parameters are as follows: Tallow,Alloy = 55 MPa; Tallow,Steel = 75 MPa Galloy = 20 GPa; G Steel = 80 GPa (a) The allowable angle of twist per unit length for the steel shaft shall be 75% of the alloy shaft. Calculate the internal diameter, d2, inner, of the steel shaft (shaft 2). (b) The power transmission for the assembly is P = 200 kW. Calculate the target rotational speed for the shafts. The maximum shear stress for the design is 50 MPa. ? z N Shaft 2 ? B Shaft 1 b ? X Figure Q2: Example of coupled shaft arrangement