Home /

Expert Answers /

Mechanical Engineering /

1-a-gear-and-shaft-with-nominal-diameter-of-35mm-are-to-be-assembled-with-a-medium-drive-fit-as-pa970

(Solved): 1) A gear and shaft with nominal diameter of 35mm are to be assembled with a medium drive fit, as ...

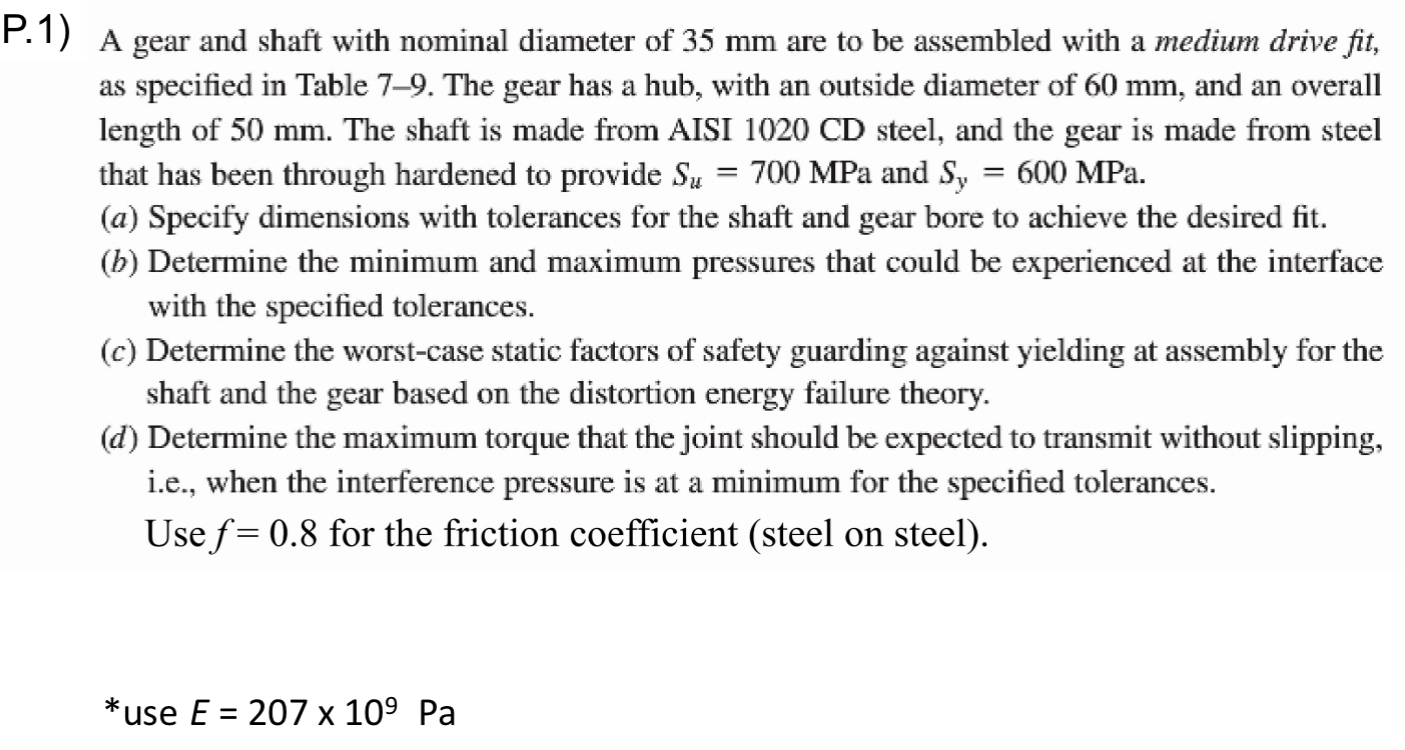

1) A gear and shaft with nominal diameter of are to be assembled with a medium drive fit, as specified in Table 7-9. The gear has a hub, with an outside diameter of , and an overall length of . The shaft is made from AISI steel, and the gear is made from steel that has been through hardened to provide and . (a) Specify dimensions with tolerances for the shaft and gear bore to achieve the desired fit. (b) Determine the minimum and maximum pressures that could be experienced at the interface with the specified tolerances. (c) Determine the worst-case static factors of safety guarding against yielding at assembly for the shaft and the gear based on the distortion energy failure theory. (d) Determine the maximum torque that the joint should be expected to transmit without slipping, i.e., when the interference pressure is at a minimum for the specified tolerances. Use for the friction coefficient (steel on steel). use

Expert Answer

To determine the dimensions with tolerances for the shaft and gear bore to achieve the desired fit, we need to select a fit type from the standard fits chart based on the nominal diameter and the desired fit. For a medium drive fit, we can use an H9/h9 fit, which has a maximum interference of 42 microns.(a) Shaft:The nominal diameter of the shaft is 35 mm, and the tolerance grade for the hole is h9. Therefore, the minimum diameter of the hole is 35.000 mm - 0.025 mm = 34.975 mm, and the maximum diameter of the hole is 35.000 mm + 0.000 mm = 35.000 mm.Gear:The nominal diameter of the gear bore is 35 mm, and the tolerance grade for the shaft is H9. Therefore, the minimum diameter of the shaft is 35.000 mm - 0.035 mm = 34.965 mm, and the maximum diameter of the shaft is 35.000 mm + 0.000 mm = 35.000 mm.(a) To achieve a medium drive fit, we can use the recommended tolerances for this type of fit, which are h9 (high) to h11 (low) for the shaft and H11 (high) to H9 (low) for the hub. The interference fit can be calculated using the formula ? = (D - d)/2, where ? is the interference, D is the hub diameter, and d is the shaft diameter.